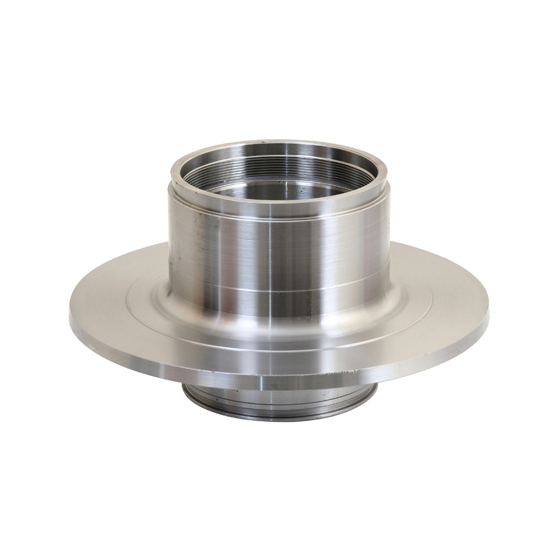

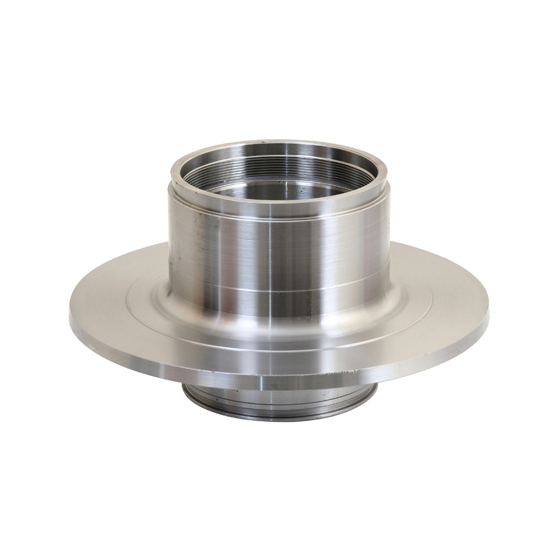

SumitechProvide customers with precision parts

Focus on precision parts processing and production

Order Hotline:+86 13418256345

These four major advantages of five-axis CNC machining centers

The five-axis CNC machining center adopts a vertical and horizontal swing structure and can be continuously flipped. The turntable adopts a worm gear drive structure, featuring a large transmission torque and is suitable for low-speed and heavy-load cutting. Torque motor drive can also be selected, featuring fast dynamic response, no backlash, and no mechanical wear in transmission. It is suitable for high-speed, high-precision, and light-load cutting.

The machine tools used are usually called five-axis machine tools or five-axis machining centers. Five-axis CNC machining is typically used in the aerospace field to process body parts, turbine parts and impellers with free-form surfaces. When describing the motion of a CNC machine tool, the right rectangular coordinate system is used; The coordinate axes parallel to the main axis are defined as the Z-axis, and the rotation coordinates of the winding x, y, and Z-axes are A, B, and C respectively. Usually, five-axis linkage refers to the linear interpolation motion of any five coordinates x, y, z, A, B, and C.

1. Significantly reduce processing time: As the drill bit shape used in global mechanical CNC deep hole drilling RIGS automatically breaks and is continuously discharged by high-pressure chip oil, there is no need to withdraw the drill bit halfway and clean the chips. The processing speed of the drilled holes can be 5 to 6 times faster than that of twist drills.

2. Edge grinding of cutting tools: Even without a dedicated tool grinding machine, it can be easily ground again. (You can sharpen it by hand when you are proficient.) Deep hole drills can be ground 50 to 60 times. Therefore, the service life of deep hole drill bits is longer. Compared with twist drills, the cost of cutting tools is not high.

3. Processing materials with high hardness: As the deep hole drill bits of the Global CNC deep hole drilling rig (three-axis deep hole drill, five-axis deep hole drill) are made of hard alloy, it can process materials with a hardness of HRC40.

4. The five-axis deep hole drill adopts an integrated design: the ram is hinged to the integral slide table through the center axis, and the servo motor drives the ram to rotate through the reducer. The rotary deviator installed on the center axis is used to control the rotation Angle, allowing the main shaft to be inclined at an Angle for inclined processing, positioning, and rigidity strength.

About Sumitech

CompanyapplicationCertificate environmentcontactProduct

Five axis machining part High precision partsCNC lathe partsMedical device partsOther industriesNews

Company Industry problem+86-134-1825-6345Monday to Saturday 8:30-20:00

(welcome to inquire)

Sumitech precision machinery technology (Dongguan) Co., Ltd © Copyright【ADMIN】【Back to top】