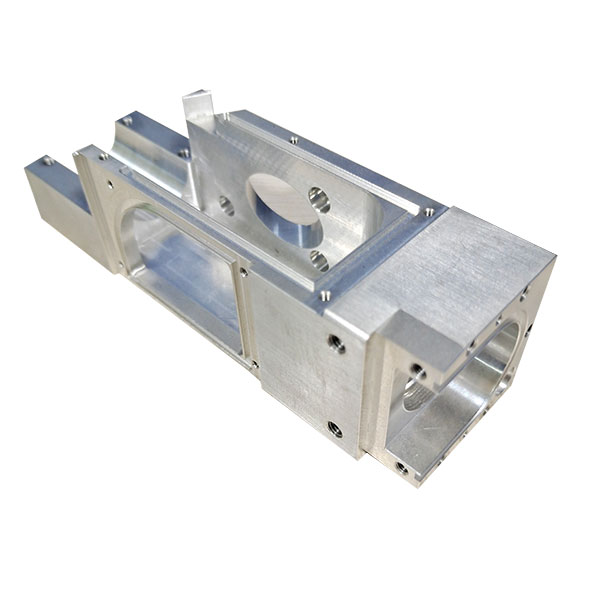

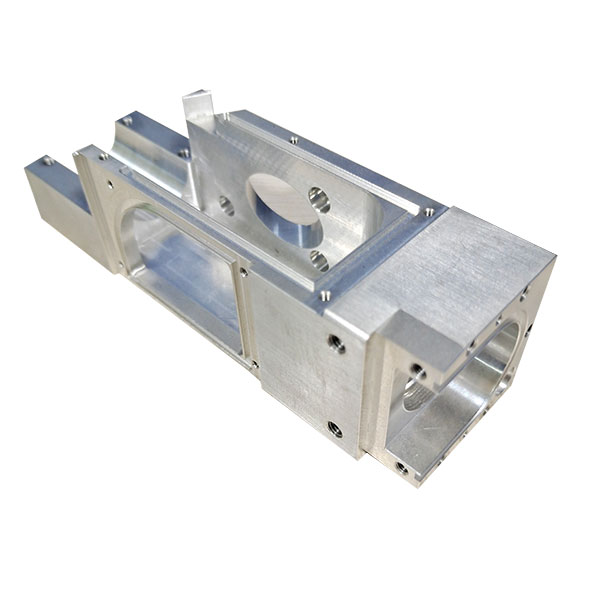

SumitechProvide customers with precision parts

Focus on precision parts processing and production

Order Hotline:+86 13418256345

A brief description of the main characteristics of the semiconductor components industry

The semiconductor components industry is typically characterized by high technological intensity, interdisciplinary integration, a small and fragmented market share, but it plays a significant role in the value chain. Generally speaking, equipment components account for about 70% of the total equipment expenditure. Taking an etching machine as an example, the ten main key components make up 85% of the total equipment cost. It is a key support for the survival and development of the semiconductor industry, and its level directly determines the basic capacity of China's innovation in the semiconductor industry.

a. Technology-intensive, with high requirements for precision and reliability.

Compared with the basic components in other industries, semiconductor components, due to their use in precise semiconductor manufacturing, have particularly prominent characteristics of being highly technology-intensive. They feature high precision, small batch sizes, multiple varieties, special dimensions, complex processes, and extremely strict requirements. Due to the particularity of semiconductor components, enterprises often have to take into account the composite functional requirements such as strength, strain, corrosion resistance, electronic properties, electromagnetic properties, and material purity in production.

The same component can be used in traditional industries, but when applied in the semiconductor industry, higher requirements are placed on key components in terms of the purity of raw materials, consistency of raw material batches, quality stability, control of machining accuracy, edge chamfering and deburring, surface roughness control, special surface treatment, clean cleaning, vacuum dust-free packaging, and delivery cycle. It has created an extremely high technical threshold.

For instance, as the line width of semiconductor processing becomes increasingly smaller, the control of extremely small contaminants in the photolithography process is extremely strict. Not only is the particle size strictly controlled, but also the metal ion precipitation of the filter products is strictly controlled. This poses extremely high requirements for the production and manufacturing of filter components for semiconductors. At present, the precision requirement for semiconductor-grade filter elements is 1 nanometer or even lower, while in other industries, the precision requirement is at the micrometer level.

At the same time, semiconductor filter elements also need to ensure consistency, as well as chemical and heat resistance, extremely strong anti-detachment properties, etc., so as to achieve the high requirements of repeatable high performance, consistent quality and ultra-pure product cleanliness required in semiconductor manufacturing.

b. The integration of multiple disciplines places high demands on compound technical talents.

There are many types of semiconductor components, with a wide coverage and a long industrial chain. Their research and development, design, manufacturing and application involve the cross-integration of various disciplines such as materials, mechanics, physics, electronics and precision instruments. Therefore, there is a great demand for compound talents.

Take the electrostatic suction cups used to fix wafers in semiconductor manufacturing as an example. They are mainly made of alumina ceramics or aluminum nitride ceramics, but at the same time, other conductive substances need to be added to make their overall resistivity meet functional requirements. This requires a very good understanding of the thermal conductivity, wear resistance and hardness indicators of ceramic materials. Only in this way can the basic raw materials that meet the technical indicators of semiconductor manufacturing be obtained; Secondly, the precision requirements for the organic processing structure inside the ceramic are high. The combination of the ceramic layer and the metal base must meet the requirements of uniformity and high strength. Therefore, for the structural design and processing of the electrostatic chuck, skills and knowledge in precision machining are needed. After surface treatment, the electrostatic suction cup needs to achieve a coating of about 0.01 microns, and at the same time, it should be resistant to high temperatures and wear, with a service life of more than three years. Therefore, the requirements for mastering and applying surface treatment technology are also relatively high. It can be seen from this that compound and cross-disciplinary technical talents are the fundamental guarantee for the semiconductor components industry.

c. The fragmentation feature is obvious. International leading enterprises mainly adopt cross-industry multi-product line development and merger and acquisition strategies.

Compared with the semiconductor equipment market, the semiconductor component market is more segmented, with obvious fragmentation characteristics. The market space for a single product is very small, and at the same time, the technical threshold is high. Therefore, there are few pure semiconductor component companies.

About Sumitech

CompanyapplicationCertificate environmentcontactProduct

Five axis machining part High precision partsCNC lathe partsMedical device partsOther industriesNews

Company Industry problem+86-134-1825-6345Monday to Saturday 8:30-20:00

(welcome to inquire)

Sumitech precision machinery technology (Dongguan) Co., Ltd © Copyright【ADMIN】【Back to top】